BLOCKS, SHEAVES, MAINSHEET TRAVELLER & GENOA CAR CHECKS

With Spring arriving fast, it’s time to check your deck hardware for signs of wear and tear, especially sheaves and blocks. A little time spent now can save a lot of grief and aggravation in the sailing season.

For blocks and sheaves

Flush through with fresh water if you have left blocks or sheaves exposed to the elements over the Winter. You can use a mild detergent to remove mould and mildew, and make sure it is ecologically friendly. Our advice is not to use oil or grease, as this attracts dirt and salt, which is abrasive.

Check for excessive movement on the bearings of both blocks and sheaves. Barton carries a range of sheave sizes from 30mm up to 70mm diameter or you can contact your local stockist for replacements. If you cannot get the exact same diameter, it’s not a problem – as long as you make sure your replacement sheave is a tight fit, width ways. Check for signs of elongation around the fixing holes and shackles at the head of your blocks, this would suggest overloading. If in any doubt, our advice would be to replace it with a higher load block – which especially applies to mast head blocks which are not so easy to inspect. Threaded and drilled shackle pins are a must aloft and should be wire seized and taped, or even cable tied to prevent unlocking. Other things to review is the condition of your split rings, if they are not tightly coiled then replace with new ones – our sailors tend to keep a packet handy. Cover both sides of the split ring with a single piece of electrical or spreader tape, and stick it onto itself, as this helps prevent snagging in ropes and halyards.

For ball bearing blocks, the sheaves should spin freely, again flush through with fresh water. Any graunching or uneven spin after flushing would suggest the block has been overloaded. Ball bearing blocks are not suitable for high static loads, such as around the mast base, so replace with a plain bearing block or one with a higher rolling load rating.

For Mainsheet Traveller and Genoa cars

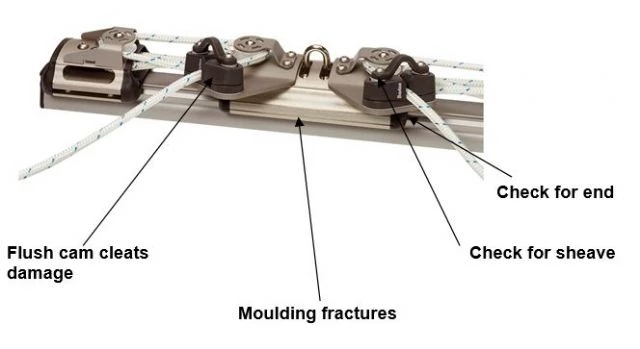

Rinse your Mainsheet traveller thoroughly with a hose pipe and fresh water, especially the underbody where the ball bearings run in the car and along the track. Take time to look at the end mouldings on the traveller car. Crash gybes are usually the cause of fractures, so add spare end mouldings to your ‘to do’ list, as you will need to remove the traveller car to do this – you may need to source a short length of track to transfer the traveller car onto for repair. Flush through your control line cam cleats with water under pressure. The cams should open and return freely, if not, unscrew them and disassemble to check for broken return springs. Worn cam jaws reduce the efficiency of the cleat and will require a new replacement. Also check the condition of the control line sheaves, they are easy to remove and inspect, and replacements may be required. Most importantly at this stage, check the condition of the track by running your hand along it as any damage may affect the life of the bearings in the car and the overall performance.

For your Genoa Cars, check for signs of excessive movement around the sheave bearing – a small amount of play is acceptable, but any more than this may cause the sheave to lock up under load. Warning signs are excessive wear to one side of the sheave where it is not rotating. Sheaves can be replaced as long as the car has been regularly flushed through and looked after, however, heavy corrosion of the aluminium around the spindle makes it impossible to repair. It’s important to also check for any damage to the track, as this will indicate the plastic inserts in the car are worn.